Understanding Precision Die Cutting

What is Precision Die Cutting?

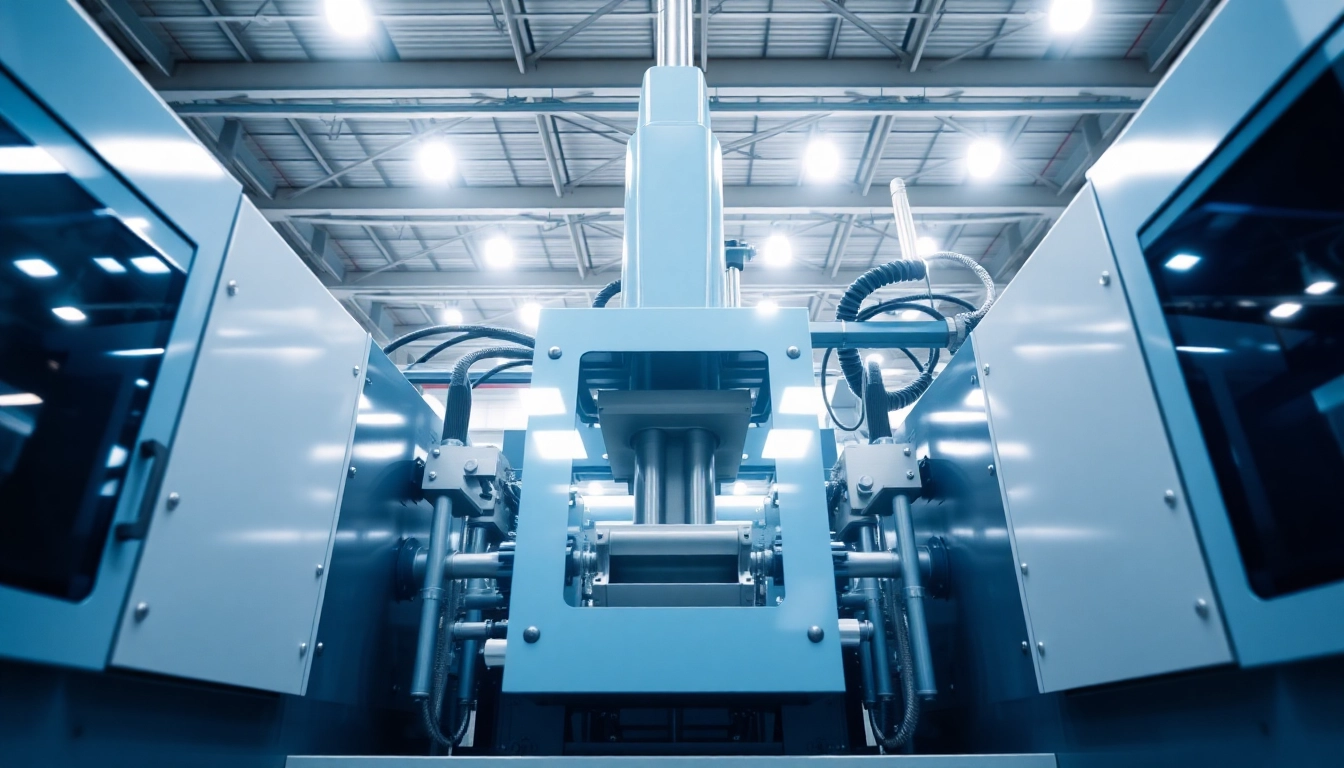

Precision die cutting is a manufacturing process that involves cutting materials into specific shapes and sizes with high accuracy and repeatability. This technique is commonly employed across various industries, including automotive, electronics, medical, and packaging. By utilizing specialized dies, manufacturers can create intricate designs and customized components with minimal waste and excellent precision. Whether it’s for high-volume production or small batch runs, Precision die cutting offers a versatile solution tailored to specific manufacturing needs.

Applications of Precision Die Cutting in Manufacturing

Precision die cutting is utilized in a myriad of applications. Here are several key uses:

- Automotive Industry: Used for gaskets, seals, and insulation materials, where precision is paramount to ensure performance and safety.

- Electronics: Involves cutting components like insulation materials, circuit boards, and protective covers, often requiring intricate designs that fit specific electronic layouts.

- Medical Equipment: Accuracy is vital for manufacturing parts like catheters, syringes, and custom packaging for sensitive medical devices.

- Packaging: Creates custom boxes, inserts, and labels that are critical for branding and protection of products during transportation.

- Textiles: Employed to cut fabrics for apparel, upholstery, and other textile products where consistent quality and distinct shapes are needed.

Benefits of Using Precision Die Cutting

Opting for precision die cutting comes with several advantages:

- High Precision: This technique allows for exact tolerances, often within ±0.005 inches, which is crucial for parts that need to fit together accurately.

- Cost-Effectiveness: In high-volume production, the cost per unit decreases significantly, making die cutting an economical option compared to traditional cutting methods.

- Material Variety: Precision die cutting can be performed on various materials, including plastics, metals, rubber, and composites, broadening its application range.

- Reduced Waste: The process minimizes waste by maximizing material usage, as the dies can be designed to fit closely together.

- Speed: Once the die is created, the cutting process can be exceedingly fast, increasing production rates and reducing lead times.

Types of Precision Die Cutting Techniques

Rotary Die Cutting Explained

Rotary die cutting employs a cylindrical die to cut materials as they pass through the machine. This method is particularly effective for continuous roll-to-roll applications. The main features of rotary die cutting include:

- Continuous Production: Because it operates in a continuous manner, rotary die cutting is ideal for high volumes, such as in packaging and labeling.

- Efficiency with Thin Materials: This method excels at cutting thinner materials with precision while maintaining a speed that traditional flatbed die cutting cannot match.

- Setup Time: Although the initial setup can be time-consuming and complex, once operational, rotary die cutting provides fast turnaround times for production runs.

Flatbed Die Cutting Process

Flatbed die cutting uses a stationary flatbed press to cut materials. The die is mounted flat against the material, allowing for precise cuts across various thicknesses. Key aspects include:

- Versatility: This method can handle thicker materials, making it suitable for numerous applications, including heavy-duty gaskets and cardboard products.

- Intricate Designs: Designed for detailed cuts, flatbed die cutting allows for the creation of complex shapes and designs, which might be challenging with other techniques.

- Lower Setup Costs: Compared to rotary dies, flatbed die setups might be less expensive, particularly for short runs, since the construction of the dies can be simpler.

Comparing Die Cutting Methods

Choosing between rotary and flatbed die cutting depends on specific project requirements:

| Criteria | Rotary Die Cutting | Flatbed Die Cutting |

|---|---|---|

| Production Volume | High volume, continuous production | Lower volume, suitable for multiple batch sizes |

| Material Thickness | Best for thin materials | Accommodates thicker materials |

| Setup Cost | Higher initial cost, suitable for large runs | Lower initial cost; excellent for prototypes and small runs |

| Precision | High precision in large scales | High precision for detailed designs |

Choosing the Right Precision Die Cutting Company

Key Factors to Consider

Selecting a die cutting company is a critical decision that can impact your production quality and efficiency. Here are essential factors to consider:

- Experience: Look for a company with a proven track record in precision die cutting and relevant industry experience.

- Capability: Evaluate the types of materials and complexity of designs the company can handle. It’s important they match your production needs.

- Technology: Investigate the type of equipment used. Advanced technologies, such as laser die cutting, may provide more options and higher precision.

- Quality Assurance: Ensure they have robust quality control processes to prevent defects in production.

- Customer Service: Responsive communication and support can facilitate smoother project execution.

Evaluating Company Expertise and Capabilities

When assessing a die cutting vendor, consider the following steps:

- Request Samples: Ask for samples of their past work to evaluate the quality and precision of their die cutting.

- Research References: Speak with previous clients about their experiences, focusing on reliability, communication, and the quality of the finished product.

- Facility Visits: If possible, visiting the facility can provide insights into operational capabilities and the company’s commitment to quality.

Requesting Quotes and Project Samples

Obtaining quotes is essential for budgeting and deciding on a vendor. Here’s how to approach this:

- Be specific about your requirements, including material types, dimensions, tolerances, and volumes.

- Request detailed breakdowns of costs to understand pricing structures, including setup fees and unit costs based on quantity.

- Ask about lead times and production timelines to ensure alignment with your schedule.

Maximizing Efficiency in Die Cutting Projects

Design Considerations for Precision Die Cutting

Effective design is critical for optimizing precision die cutting projects:

- Optimize Layout: Design parts to minimize scrap and maximize material usage. Use layout software for optimal nesting of parts.

- Consider Tolerances: Set clear tolerances based on the part’s function and assembly. This ensures compatibility with other components.

- Test Designs: Prototyping initial designs can help identify potential issues that may arise during mass production.

Common Mistakes to Avoid

To ensure a successful die cutting project, be wary of these common pitfalls:

- Neglecting Material Selection: Choosing materials that are not compatible with your die cutting process can lead to increased costs and delays.

- Ignoring Tolerance Requirements: Underestimating tolerances can result in fitting issues during assembly, leading to costly rework.

- Inadequate Design Testing: Skipping the prototyping phase can result in unexpected design flaws appearing during full production runs.

Performance Metrics to Measure Success

To keep die cutting projects on track, monitor these performance metrics:

- Quality Rates: Track the percentage of parts that pass quality inspection without rework.

- Lead Times: Measure the speed from order receipt to delivery, ensuring adherence to promised schedules.

- Production Yield: Calculate the ratio of good parts produced versus total parts made, as it impacts overall efficiency and cost.

Future Trends in Precision Die Cutting Technology

Advancements in Die Cutting Equipment

The die cutting industry is continuously evolving with advancements aimed at enhancing speed, precision, and efficiency. Innovations include:

- Laser Die Cutting: This technology allows for intricate designs and faster processing times, often with less material waste.

- Hybrid Technologies: Combining die cutting with additional processes, such as laminating or printing, streamlines production workflows.

- Smart Die Cutting Machines: Incorporating IoT technology helps monitor machine performance in real-time, facilitating predictive maintenance and reducing downtime.

Integration of Automation and AI in Die Cutting

As automation becomes more prevalent, AI is playing a significant role in optimizing die cutting processes:

- Process Optimization: AI algorithms analyze production data to identify patterns and optimize cutting paths, reducing cycle times.

- Quality Control: Machine vision systems can inspect products in real-time, ensuring quality by identifying defects immediately during production.

- Supply Chain Management: Integrating AI in supply chain logistics can streamline material sourcing and inventory management for die cutting operations.

Environmental Considerations and Sustainable Practices

As sustainability becomes increasingly important in manufacturing, precision die cutting is evolving to meet these demands:

- Material Efficiency: Emphasis on minimizing waste through better cutting layouts and material selection contributes to environmental goals.

- Recyclable Materials: The use of materials that are recyclable or biodegradable is on the rise, aligning with global sustainability efforts.

- Energy-Efficient Machines: Newer die cutting machines are designed for lower energy consumption, reducing the carbon footprint of manufacturing processes.